Flameproof is an explosion protection type for electrical equipment. Its enclosure can withstand the internal explosion of the explosive mixture that enters the enclosure through any joints or structural gaps without sustaining damage, and will not ignite the external explosive gas atmosphere formed by one or more gases or vapors.

Flameproof enclosures must have explosion-proof and blast-resistant properties. Generally, the enclosures of flameproof products are relatively bulky, making them suitable for fixed-installation and fixed-use products and equipment. The width, gap and roughness of flameproof joints are the three key elements of flameproof enclosure design.

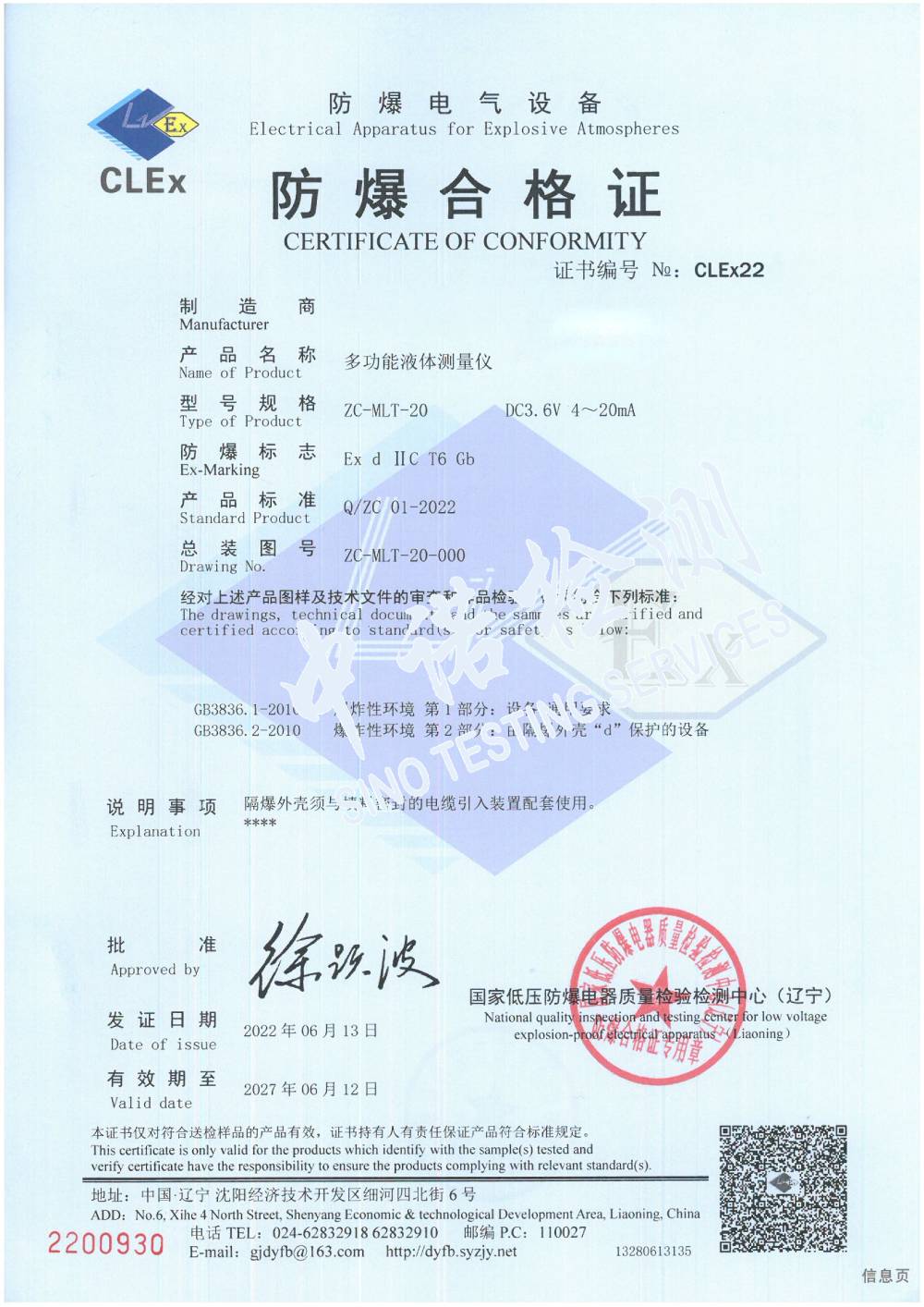

Different design requirements for these three key elements apply to products used in Mining Category I as well as non-mining Categories IIA, IIB and IIC explosive gas atmospheres. For specific details, please refer to the design standards of GB/T 3836.1 and GB/T 3836.2.

STS has long specialized in the design, testing and certification services of explosion-proof products. We have a team of professional structural engineers in the flameproof field, who are familiar with explosion-proof standard requirements and certification processes. We can provide services including flameproof enclosure design, drafting, rectification guidance and certification agency services. Our successful cases cover X-ray emission and reception boxes, lamps, motors, electric window openers, control boxes, capacitive dew point meters, metering pumps, electric actuators, tax-inclusive analyzers and other products.

If you also have such needs, please feel free to contact us via private message at any time!

|

||||||

|

||||||